Where does sound come from?

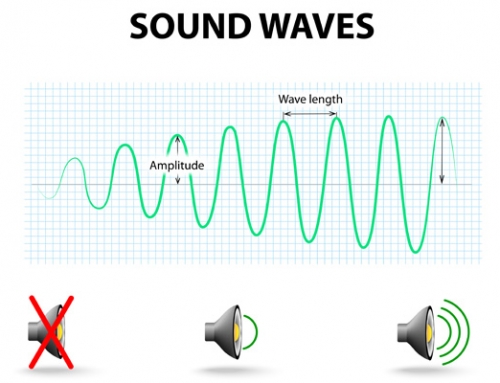

Noise is all around us, but have you ever thought about where sound comes from? Or what sound is? In the simplest terms, sound occurs when the human ear detects sound pressure waves. These sound waves reach the inner ear, the cochlea, where hair cells vibrate, which turns the sound waves into electrical signals that the brain interprets as sound. Sound wave energy is measured in terms of amplitude and frequency. A sound wave’s amplitude measures how much force is behind a wave; amplitude is often measured in decibels (dB) of sound pressure (corrections using various scales are often applied). Generally, 0 dB is the softest level that a person can hear. Normal speaking voices are around 60 dB while a concert may be as high as 120 dB! Frequency is the number of sound vibrations in one second and is measured in Hertz. A healthy ear can hear sound frequencies from 20 Hertz to 20,000 Hertz. Exposure to high decibel sound pressure at the right frequency sound waves over a period of time can result in damaging the hair cells that interpret sound, resulting in permanent hearing loss.

Hearing loss is a major concern among health authorities today.

According to the Center for Disease Control, “Four million workers go to work each day in damaging noise. Ten million people in the U.S. have a noise-related hearing loss. Twenty-two million workers are exposed to potentially damaging noise each year.” Once hearing is loss, it cannot be regained. Often, tinnitus, a loud ringing or buzzing in the ear, will result from permanent hearing loss. Damaging sound levels originate from many places: occupational noise, environmental noise, community noise, and product noise.

Damaging sound comes from many sources.

Occupational Noise

The most common type of damaging noise source that the general public is aware of is occupation noise, also known as workplace noise. Prolonged exposure to moderate to high levels of sound will result in hearing loss. Although most common in the manufacturing sector, other occupational populations are exposed to dangerous sound levels: those in mining, oil and gas production, transportation, construction, the music industry and even some service industries.

Industrial Hygiene Exposure Monitoring

It is the Industrial Hygienist’s objective to access employees’ occupational exposure to health hazards such as damaging sound exposure. It is best practice for the hygienist to measure the health risks of employees that pose the greatest risk of injury because exposure is variable and it presents the measurement of a worse-case scenario. Depending on the results of the risk assessment, a hygienist will perform further investigations. For example, if an acceptable or uncertain sound level is found, the hygienist will repeat or further investigate the results to confirm or refute the results. If an unacceptable sound level is present, the hygienist will recommend controls to lower the employees’ noise exposure. Results will be gathered again until controls put in place establish acceptable sound levels.

Regulatory Compliance

Because sound varies over time, noise exposure is calculated as an average; this sound exposure average is often expressed in terms of a ‘dose.’ The Occupational Health and Safety Administration’s Permissible Exposure Limit, or PEL, states that a worker cannot be exposed to a dose more than a 90 dB (a weighted) average for an 8-hour work shift. For every 5 dB increase in sound level, the allowable exposure time is divided in half. Therefore, in a work environment with noise levels at 95dB (a weighted), a worker could continue working for four hours. After these four hours, the worker would need to work in an area below the default threshold of 90dB. Similarly, if the employee worked in an area with noise levels below 90dB (a weighted), the employee could work longer than 8 hours in the given area. A 40 year exposure at OSHA’s PEL, puts approximately 25% of workers at risk for occupational noise induced hearing loss. On the other hand, the National Institute for Occupational Safety and Health has stricter standards. It recommends a dose no more than 85dB (a weighted) average for an 8 hour shift. Furthermore, its time weighted average is calculated at 3dB exchange rate as opposed to the 5dB exchanged rate that OSHA uses. Scientists are finding that the 3db exchange rate is more accurately calculating time weighted average for noise. Under the NIOSH standards, approximately 8% of workers are at risk for occupational noise induced hearing loss after 40 years of exposure.

Risk Assessment (The following guidelines are OSHA guidelines. NIOSH practices will be similar but with different thresholds.)

Determining when and how to test for risk assessment can be confusing. When normal conversation in the workplace becomes difficult, it is a good indication that a noise level survey (also known as a sound level survey) must occur. This is because when sound levels are above 80dB, people have to speak very loudly. At only 85dB, people have to begin to shout to communicate! A typical noise assessment begins by a preliminary screening. This is to determine how the workplace is laid out and operates. The risk assessor will create a detailed floor plan and determine sources of noise for different work areas. It is generally a good idea to tour the survey area with a knowledge staff member/employee of the workplace. Take notes regarding what machinery, instruments, tools, and equipment are running and that which are not. When the risk assessor comes upon a great source of noise, he or she should take a spot reading of the noise with a sound level meter. Estimates of how long employees stay in a given noise area should be made as well. If a time weighted average of 80dB (a weighted) is indicated from the screening then more investigatory testing should occur. When conducting a noise level survey, sample the noise exposure from each representative job classification and/or work area. The chosen representative for each job classification and/or work area should be the employee that is at most risk for loud sound exposure. Generally, each chosen employee will wear a dosimeter. These employees will be informed of the survey and be informed that they are not be recorded. Instructed them not tamper, cover, or muffle the meter or its wind screen in anyway; employees should go about their job as they normally would. Dosimeters should be positioned near the employee’s hearing zone. OSHA defines this zone as a two foot radius surrounding the head. If sound levels vary between the employee’s left and right hearing zone, the dosimeter should be positioned on the side with the greater amount of noise. Periodically, check and obtain dosimeter results during different phases of work for each employee. Dosimeters with different threshold settings will be used for individual employees depending on whether he or she’s work complies with OSHA’s Permissible Noise Level guidelines (Table G-16).

|

TABLE G-16 – PERMISSIBLE NOISE EXPOSURES (1) |

|

|

Duration per day, hours |

Sound level dBA slow response |

|

8 |

90 |

|

6 |

92 |

|

4 |

95 |

|

3 |

97 |

|

2 |

100 |

|

1 ½ or 1.5 |

102 |

|

1 |

105 |

|

½ or 0.5 |

110 |

|

Less than or equal to 0.25 hours or 15 minuets |

115 |

|

Footnote(1) When the daily noise exposure is composed of two or more periods of noise exposure of different levels, their combined effect should be considered, rather than the individual effect of each. If the sum of the following fractions: C(1)/T(1) + C(2)/T(2) C(n)/T(n) exceeds unity, then, the mixed exposure should be considered to exceed the limit value. Cn indicates the total time of exposure at a specified noise level, and Tn indicates the total time of exposure permitted at that level. Exposure to impulsive or impact noise should not exceed 140 dB peak sound pressure level. |

|

|

In other words F(e)=(T(1)divided by L(1))+(T(2)divided by L(2))+ … + (T(n) divided by L(n)) where: Where, F(e) = The equivalent noise exposure factor. T = The period of noise exposure at any essentially constant level. L = The duration of the permissible noise exposure at the constant level (from the above table). If the value of F(e) exceeds unity (1) the exposure exceeds permissible levels. |

|

|

If the variations in noise level involve maxima at intervals of 1 second or less, it is to be considered continuous. |

|

A dosimeter with a 80dB (a weighted) threshold would be used for employees that meet the safety requirements of OSHA. A dosimeter with a 90dB (a weighted) threshold would be used for employees that are exposed to noise that exceeds the safety standard of OSHA. Hence, a 80dB threshold determines whether a time weighted average is below 85dB whereas a 90dB threshold determines whether a time weighted average is above the PEL, 90dB. Fortunately, most modern dosimeters will simultaneously measure 80dB and 90dB thresholds, making surveys easy. Sampling should occur for as long as needed to establish whether OSHA safety standards are met. If the total weighted average is at or exceeds 85dB, a hearing conservation should be put into effect. If the total weighted average exceeds the PEL of 90dB then engineering or administrative controls should be put into effect.

Hearing Conservation Program

As previously stated, if the workplace noise exceeds 85dB or its calculated equivalent, a 50% dose, then a hearing conservation program must be put into place. A hearing conservation program consists of five components: a monitoring program, an audiometric testing program, hearing protection devices, employee training and education, and proper record keeping. A monitoring program, either using dosimeters for personal monitoring or a sound level meter for work area monitoring, must be implemented. Noise measurements must integrate all continuous, intermittent, and impulsive noise levels from a range of 80 to 130 dBA. Repeated monitoring must occur anytime there has been a change in production, process, equipment, or controls that increase noise exposure. During monitoring, if the noise is above the PEL, employees have the right to see the results as well as observe monitoring procedures. Within six months of monitoring that exceeds the PEL, the employer must establish an audiometric testing program that tests employees’ baseline hearing. This test will measure the sharpness and acuity of one’s hearing. After the baseline test, the employer must provide a test annually. At least 14 hours of noise below the PEL must precede each test. All tests must be provided free of charge. Hearing protection devices are considered the last line of defense against noise. They should implemented immediately while noise controls are being designed and implements. In the case that noise controls cannot be made or are ineffective, hearing protection devices should be provided indefinitely. At least two varieties of two different types of hearing protection devices should be provided to employees free of charge. Hearing protection devices should be evaluated for their effectiveness anytime there is a change in production, process, equipment, or controls that increase noise exposure. A training and education program should be provided for all employees with noise exposures at or above the 85dB time weighted average level. Training/education must include teaching about the effects of noise on hearing. Information about hearing protection devices and audiometric testing should be provided. Training should be repeated annually for every employee in the hearing conservation program and all training materials should be provided to the employees. All exposure measurement results, audiometric test results, and employee records should be kept logged per OSHA record keeping regulations.

Noise Controls

The first line of defense against dangerous noise exposure is noise controls. Reduction of noise by even a few decibels can lower the risk of hearing loss, improve communication, and increase productivity. Engineering noise controls involves either physically replacing/modifying the noise source or changing the noise source’s transmission path to reduce the noise level that reaches the worker’s ears. While replacing equipment may not be an option for most, there are some relatively inexpensive methods to create engineering noise controls. For example, maintaining anf lubricating machinery can dampen its sound output. Often placing a barrier between the noise source or enclosing the noise source can greatly reduce dangerous noise levels. Administrative noise controls are changes in the workplace formed from policy that help control noise exposure. For instance, the loudest piece of equipment might only run during the smallest shift in order for there to be the least amount of people exposed to high noise levels. Another example is only allowing a worker to be in a loud area for a predetermined amount of time to limit his or her noise exposure.

Environmental (Ambient) Noise

The rhythmic thumping of a jackhammer, the chugging of a locomotive traveling down the railroad tracks, or even the growl of diesel truck– environmental sound surrounds everyday people who probably do not give much thought to how it affects their hearing. Luckily, there are regulatory precautions put in place to measure and limit loud sound that could potential induce hearing loss.

Planning and Environmental Impact Studies

Construction in a community can often create a large amount of complaints. One of the most common problems is noise, especially when it affects activities in the community and there is a lack of understanding about the project’s time frame. This issue can be further compounded when the community believes the contractor is being insensitive while the contractor believes he or she is following local laws and ordinances. For this reason, it is important for early identification and assessment of potential noise problems. By addressing noise and creating a plan to combat it, contractors reduce legal costs and can include costs or noise reduction in their bid. Furthermore, by publishing the expected noise and the plan to address the given noise, the community will be more accepting of the environmental noise.

Site Development

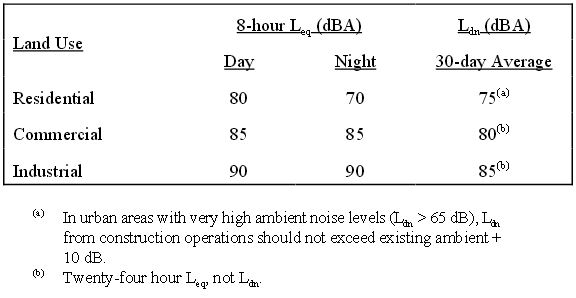

The type of project and stage of environmental review of any site development or construction project will determine the level of detail needed for a construction noise assessment. For example, a major real estate development project in a heavily populated downtown with loud machinery that is expected to last several months will need far more detail than a smaller project in a rural area. A large construction noise assessment usually compares the predicted sound levels using the appropriate descriptor, a standardized prediction method, and a set of recognized criteria for assessing the impact. The appropriate descriptor for a large construction project is the LEQ parameter because it can measure the sound levels of individual pieces of equipment and easily be combined and calculated to determine the noise output of all machinery during a given time period. This variable also has the ability to represent all noise out put during a phase of construction as well as describe the average noise output of all phases of construction. Assessment models of major construction projects vary according to whether is major, minor, or transit related. In general, assessors should predict the 8 hour LEQ and 30 day LDN and compare to the chart below for acceptable noise standards.

Wind Turbine Noise

Wind Turbines are rather new, and therefore, there are few studies on the effects its noise has on people. The few studies from the past tend to show no effect on its subjects. However, these studies usually only measure the direct effect on people for a very short amount of time. Increasingly, people that live near wind turbines and wind farms are finding that the constant low frequency hum of wind turbines is having adverse effects including but limited to headaches, dizziness, insomnia, and tinnitus. Furthermore, the constant stress of these symptoms affects cardiovascular, psychiatric, and cognitive health. For this reason, wind turbine noise studies are becoming increasingly popular. In fact, wind turbine noise is beginning to be seen as a health issue rather than a nuisance issue. At the annual Noise-Con, a convention dedicated to noise research, there is nearly as many sessions dedicated to wind turbine noise as there is to transportation noise.

Transportation Noise

Road construction and transportation are major sources of environmental noise. Hence, the Federal-Aid Highway Act of 1970 developed noise regulations pertaining to vehicles as well as transportation projects that request federal funds. According to this act, effective highway noise needs to be controlled with a 3 part approach: land use planning, source control, and highway noise mitigation. The Federal Highway Association encourages state and local governments to take into consideration how transportation noise will affect the surrounding areas and how a road construction project will affect future noise controls. The Noise Control Act of 1972 placed the Federal Environmental Protection Agency in charge of establishing regulations pertaining to vehicle, road construction, and highway noise emissions. Federal policy states that funds may only be used for noise reduction where there is frequent use and predicted noise levels that approach the EPA’s noise-abatement criterion, or NAC, which is typically 67dB (a weighted) for the worst single hour of the year where noise reduction is feasible and reasonable. Sound barrier walls are the most common and expensive type of noise mitigation, costing 1.3 to 2 million dollars a mile. Other methods of controlling highway noise include reducing speed limits and changing the elevation of the road.

Aircraft Noise

Propellers, jet engines, frame noise, luggage caddies- obviously, airports and aircraft produce a great amount of noise. The Federal Aviation Administration even directs those interested in aircraft noise to a website dedicated to aviation noise, http://www.noisequest.psu.edu/ . The FAA measures noise with the Day-Night Average Sound Level (Ldn) variable because airports operate at all hours of the day and noise between 10pm and 7am is artificially increased by 10dB since there is a lack of ambient noise. Hence, the noise between this time period is weighted to take into account the lack of background noise. Areas surrounding the airport are supposed to be under an Ldn measurement of 65dB (a weighted). If an area is above this threshold, noise controls should be put into place to restrict the sound. Noise controls include administrative controls such as regulating full-power ‘run-up’ to specific periods of time to engineering controls such as installing enclosures that absorb and redirect noise away from the community.

Often, other noise variables are measured when performing an airport noise surveys. These noise variables include the Maximum A-weighted Sound Levels (Lmax), Sound Exposure Level (SEL), Equivalent Sound Level (Leq), Time Above a Specified, Sound Level (TA), Sound Pressure Level (SPL), and Number-of-Events Above a Specified Sound Level (NA). The Time Above a Specified Sound Level (TA) and Number-of-Events Above a Specified Sound Level (NA) are often important to communities that live very close to an airport because these variables, depending on the programed threshold, will indicate how many airplanes takeoff/land and the amount of time that passed during these noise events.

Community Noise Code Enforcement

Performance venues, sporting events, boom cars, landscaping noise, drilling and blasting, noisy neighbors- unwanted noise can be a quite bothersome, especially when trying to work- or sleep. Many jurisdictions have noise limits for residential, commercial, and industrial zones. These noise limits may be even lower at night. Nuisance noise can be hard to define because perception is subjective to the listener depending on the noise source, intensity, frequency, and time of day. What may bother one person might not affect another. To make matters more complicated, these noise limits vary from city to city. Noise considered lawful in a city may be illegal and warrant a ticket in a small town. Often, police officers will take a simple single average or measure the maximum decibel level to determine if the noise is acceptable. These tests can be measured with a basic sound level meter. For nuisance noise surveys that span from day into night, more advanced sound level meters that have the ability to calculate the Day-Night Average or LDN may be useful. If noise is an on-going problem, sound level meters with the capability for data logging and audio recording may be beneficial.

Product Noise

Sound level and tone can play a large part in the potential success or failure of a product. From laptops to drills, engineers recognize the need to consider and control the sound level and tonal quality during product design and development. An initiative to label the noise output as part of product safety ratings has forced many manufacturers to focus in on creating a quieter product. In addition, many companies seek to buy quieter equipment to limit their employee’s noise exposure and risk for noise-induced hearing loss. The demand for quieter, safer products is a reality.

Product Labeling

Labels that disclose noise levels emitted from a product promote safety and informed consumer choice. Labeling of noise emissions is mandatory for certain products in countries such as China, Argentina, Brazil, and the European Union. This type of product labeling is likely to become prevalent in more countries and for more product types in the near future.

CE Marking

For instance, in order for a product to be marketed in Europe, it must bear a CE marking. This marking declares that the product meets the conformity safety standards set out by the European Union. Noise-related safety standards are found in the DIRECTIVE 2000/14/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL. In this directive, noise is measured with the surface sound pressure level variable and the sound power level variable, which is an a-weighted sound variable that indicates the total acoustic energy that a product radiates to its surroundings. Sound pressure level and sound power level standards are specific to different types of products. When measuring the sound power level of a product, a special room or anechoic chamber that reduces external background noise may be necessary to gather quality results. Sometimes, reverberation chambers constructed of hard surfaced walls that reflect noise are used to measure the sound power of certain products such as vehicles or construction machinery.

Toy Safety Noise Standards

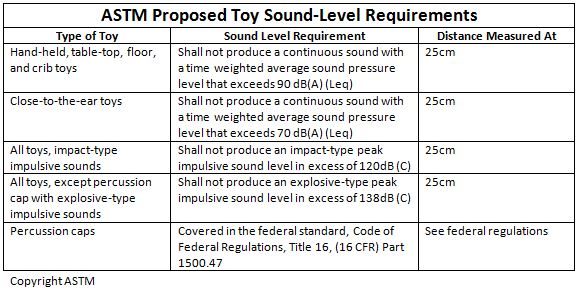

As more people identify noise as a potential cause of hearing loss, a larger amount of research is being dedicated to noise and populations other than workers. Children’s noise exposure is a topic becoming increasingly popular because children are not aware of the detrimental effects of loud noise exposure. Additionally, unnoticed hearing loss can have a negative effect on their future education and life. A 1998 study by John W. Hawks of Kent State University included taking sound level measurements of 22 toys recommended for children in a standard-sized playroom. Many of the toys were intended for those under the age of 3 years. Of the 22 toys, 20 of the items exceeded standards set forth by Canada, which bans toys that exceed 100 dB. Currently, the United States does not have general toy noise level standards but the American Society for Testing and Materials, or ASTM is in the process of standardizing test procedures and creating their own set of regulations. There are federal noise regulations on toy cap guns.