Noise level standards are developed by

many agencies and industries to regulate noise emissions and protect noise induced hearing loss. Below is a review of several standards from regulatory agencies. These standards may change. The reader must confirm the information below by visiting the regulatory agency’s website, some links are provided.

OSHA Noise Level Standards

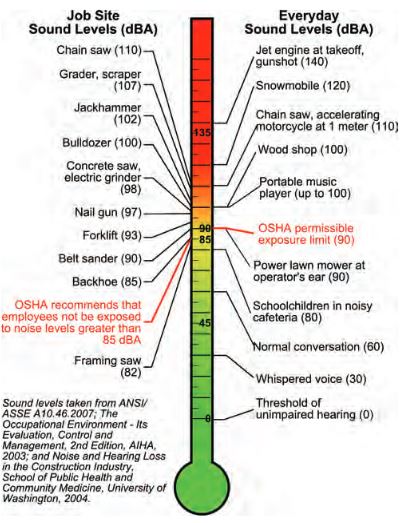

The Occupational Safety and Health Administration’s mission statement is “to assure safe and healthful working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance.” Here is a link to OSHA Noise Level Standards and Hearing Conservation. In accordance with its goal of safety, OSHA, a part of the Federal Labor department, has set out noise level standards and the implementation of hearing conservation programs. OSHA calculates noise exposure as an average because noise levels vary throughout the day. OSHA’s Permissible Exposure Limit (PEL) is a maximum noise level of a 90dB (A Weighted, slow response) average with 5dB exchange rate over an eight hour shift. At 85dB (A Weighted, slow response) average over an eight hour shift, employers are required to take action by implementing a hearing conservation program. A weighting is used because it best mimics the frequency response of the human ear, being most responsive to the mid-frequencies of 500 to 4,000 Hz.

Noise Exposure Doses

Noise exposure is discussed in terms of a dose. A full dose is the OSHA’s permissible exposure limit: a time weighted average of 90dB. Time weighted averages are always calculated over 8 hours. Therefore, four hours of work at 90dB would be considered a 50% dose of noise exposure because eight hours at this level is allowed. The dose doubles every time the time weighted average increases by the exchange rate. Therefore, every time there is a 5dB increase in noise level, the allowable exposure time is divided in half because a 5dB increase in noise level is twice as loud. Hence, in a work environment with noise levels at 95dB, a worker could continue working for four hours before reaching a full dose of noise exposure. After reaching a full dose, this worker would need to work in a much quieter environment. Likewise, if an employee works in an area with noise levels below the 90db (A Weighted) average then the employee could continue working for a longer period of time before reaching a 100% dose of noise exposure. According to OSHA, a 40 year exposure at the Permissible Exposure limit, puts approximately 25% of workers at risk for occupational noise induced hearing loss.

Below is OSHA’s Table G-16. This table compares different sound levels and the corresponding duration that equals a maximum noise exposure dose. It also provides a formula for figuring out if noise exposure is permissible when a worker is exposed to two or more sound level averages over a period of time.

|

TABLE G-16 – PERMISSIBLE NOISE EXPOSURES (1) |

|

|

Duration per day, hours |

Sound level dBA slow response |

|

8 |

90 |

|

6 |

92 |

|

4 |

95 |

|

3 |

97 |

|

2 |

100 |

|

1 ½ or 1.5 |

102 |

|

1 |

105 |

|

½ or 0.5 |

110 |

|

Less than or equal to 0.25 hours or 15 minuets |

115 |

|

Footnote(1) When the daily noise exposure is composed of two or more periods of noise exposure of different levels, their combined effect should be considered, rather than the individual effect of each. If the sum of the following fractions: C(1)/T(1) + C(2)/T(2) C(n)/T(n) exceeds unity, then, the mixed exposure should be considered to exceed the limit value. Cn indicates the total time of exposure at a specified noise level, and Tn indicates the total time of exposure permitted at that level. Exposure to impulsive or impact noise should not exceed 140 dB peak sound pressure level. |

|

|

In other words F(e)=(T(1)divided by L(1))+(T(2)divided by L(2))+ … + (T(n) divided by L(n)) where: Where, F(e) = The equivalent noise exposure factor. T = The period of noise exposure at any essentially constant level. L = The duration of the permissible noise exposure at the constant level (from the above table). If the value of F(e) exceeds unity (1) the exposure exceeds permissible levels. |

|

|

If the variations in noise level involve maxima at intervals of 1 second or less, it is to be considered continuous. |

|

Dosimeters are used to record noise and determine a worker’s noise exposure. Different decibel thresholds are used depending on the noise environment. In areas where noise levels are not expected to exceed OSHA safety standards, an 80dB (A Weighted) threshold will be used. This will determine if a hearing conservation plan needs to be put into effect because it will measure if the noise is above/below 85dB . In areas where noise levels are expected to exceed OSHA safety standards, a 90dB (A Weighted) threshold is used to determine if the noise is at or above 90dB. Most dosimeters are capable of simultaneously measuring both thresholds, making surveys easy.

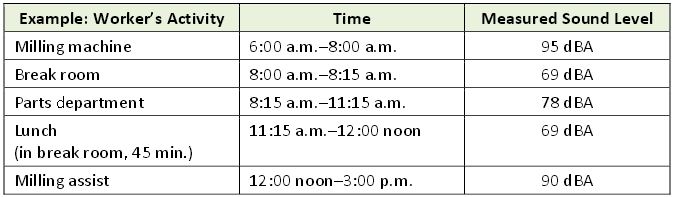

Consider this example: A worker in a machine shop is exposed to 95 dB for 2 hours, 69 to 78 dB for 4 hours (including a 15 minute break and 45 minute lunch), and 90 dB for 3 additional hours

Because the noise during each break and the noise in the Parts department did not exceed the 80dB threshold, these periods of time are not used in the calculation. While at the milling machine, the worker was exposed to 95dB. Looking at OSHA Table 16, we know that a worker can be exposed to 95dB for 4 hours. While assisting in milling, the worker was exposed to 90dB. OSHA states that a worker can be exposed to this level for 8 hours. Using the equation above then:

2/4 + 3/8 = 7/8. Hence, this worker was exposed to 7/8 or 87.5% of the allowable dose. If the number was greater than 1, it would indicate that the worker went above the permissible exposure limit.

(Example courtesy of the OSHA Technical Manual)

Risk Assessment

Conduct a meeting regarding the possibility of a noise survey with employees before any preliminary screenings. This meeting should be both to educate employees about noise surveys and collect information needed for a successful and accurate survey. Explain the nature, scope, and purpose of the survey. Request information such as audiogram records, employer noise sampling data, documents of education and/or training pertaining to hearing loss, information about areas where noise may be an issue, a schematic diagram of workplace, etc. Ask if hearing protection is available or required. Question the management/union representative about noise and hearing conservation efforts.

A preliminary walkaround survey with an employee or staff member should precede a noise level survey. The purpose of this walkaround survey is to become familiar with the layout and operation of the work area as well as locate any sources of noise. Create a thorough floor plan that can be marked indicating areas of concern. Take notes regarding machinery, instruments, tools, and equipment that make noise. Perform spot readings with a sound level meter to estimate noise conditions and determine the correct noise thresholds for the dosimeters.

Detail when these objects make noise and how long the duration of the noise lasts. Also, estimate the amount of employees that are exposed to each area of noise. Take pictures of employees with improper ear protection in areas of noise. If the spot measurements indicate the possibility of a time weighted average of 80dB (A Weighted) or more, then more testing should be planned. When a sound level meter for spot readings is not available, noise can be estimated by standing about arm’s length from another person. If a person has to raise their voice to be heard, it can be assumed that the noise level is above 85dB. Interview the employees in areas of questionable noise exposure. Ask questions such as:

In your opinion, is today noise typical?

In your opinion, what are the loudest jobs at work?

Are you supposed to wear hearing protection? If so, how often?

Did anyone explain why you have hearing protection and where and when you need to use it? How did they do that?

What is the frequency and duration of noise exposure?

When would be the best day to return to sample for noise? (Note: You want the worst typical noise exposure day to sample—when the most machines are running)

Has the company made any effort to reduce noise levels? What is your opinion of the results of these efforts?

Noise Level Standards Survey

Before conducting a survey, make sure all instruments- sound level meters, dosimeters, octave band analyzers- are calibrated and in working order. Check the batteries. Document calibration on the proper OSHA forms.

Develop a noise sampling strategy. Make certain to sample the noise exposure of each representative job classification and/or work area. The chosen representative for each job classification and/or work area should be the employee that is at most risk for loud noise exposure. Record necessary information about each employee that will be monitored. Always inform management about what areas as well as who will be monitored so that arrangements can be made if necessary.

Explain to each worker what is occurring and why he or she is being sampled. Explain that the dosimeter is not a speech recording device and that the worker should go about his or her daily routine as normal. Let each worker know that pictures will be taken during the day to prove that the dosimeter was worn. Inform the workers that as the day goes by that they will be checked regularly to make sure the dosimeter is not affecting their ability to work and that they shouldn’t take off the dosimeter unless absolutely necessary. Schedule times to remove the dosimeter such as lunch or scheduled breaks. Dosimeters may be kept on during lunch if lunch is part of their 8 hour pay shift. Record the time periods that the dosimeter was worn.

Record at least 10 sound level meter measurements in each sampled worker’s hearing zone, a 2 foot radius surrounding his or her head, and note sound level meter readings during different phases of work for each sampled worker. Take notes determining the noise level of each noise source. More readings should be taken when noise widely fluctuates.

Include a brief description of each noise source and record octave band analysis readings if the dose is significant (greater than 132%) so that noise controls can be put into place. This description should include maintenance and condition of noise source, noise source working cycles/phases/uses, distance of noise source from the workers, and existing noise controls.

Remove dosimeters at the end of the shift and fill out the appropriate OSHA forms. Post-calibrate all the dosimeters and sound level meters and document the process as necessary. Ask the worker if this was a typical day for noise. (If not, schedule another day for a noise survey) Conduct a post survey interview discussing hearing conservation and possible noise controls.

The American Conference of Governmental Industrial Hygienists (ACGIH) Guidelines

At this time, ACGIH’s guidelines are not available for discussion. However, it is believed that for occupational exposure to noise in their Threshold Limit Values (TLVs). The following is a summary of these limits: Exposures are based on a 3 dBA exchange rate. The PEL is 85 dBA. Based on the 3 dBA exchange rate, allowable TLVs for noise range from 80 dBA for a 24-hour period to 139 dBA for 0.11 seconds. No exposure to continuous, intermittent, or impact noise in excess of a peak C-weighted sound level of 140 dB is allowed. A hearing conservation program is required when workers are exposed to noise above the TLV levels. The above requires further documentation and additional references.

NIOSH Noise Level Standards

The National Institute for Occupational Safety and Health is a division of the Center for Disease Control and Prevention, which is part of the Federal Health Department. Here is a link to NIOSH Noise Level Standards. It has a mandate to provide “every man and woman in the nation safe and healthful working conditions and to preserve our human resources.” NIOSH researches and recommends noise level standards that it passes on to regulatory agencies such as OSHA. NIOSH’s Recommended Exposure Limit (REL) is 85db (A Weighted, slow response) as an 8-hr time-weighted average. It also sets a maximum ceiling limit on impulsive noise of a 140dB. Unlike OSHA, NIOSH uses an exchange rate of 3dB for calculation of time weighted noise exposures. According to NIOSH, a 40 year exposure to a REL of 85db (A Weighted) puts only 8% of workers at risk of developing noise induced hearing loss. When noise levels are at or above the REL, NIOSH recommends a hearing loss prevention program that includes exposure assessment, engineering and administrative controls, hearing protectors, audiometric tests, education about noise, record keeping, and program audits and evaluations.

Noise Exposure Doses

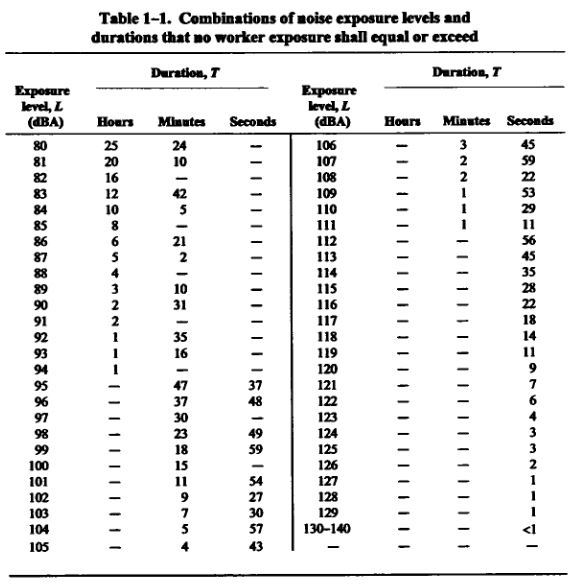

Like OSHA, NIOSH discusses noise exposure in terms of a dose. A full dose is NIOSH’s recommended exposure limit of 85dB over eight hours. Hence, four hours of work at 85dB would be considered a 50% dose of noise exposure because eight hours at this level is allowed. The dose doubles every time that the noise increases by the 3dB exchange rate. Therefore, an employee could work in an area with a 88dB noise level for four hours. Below is NIOSH’s Table 1-1 that lists noise levels and the maximum amount of time an employee can work in these conditions without exceeding the recommended exposure limit.

Calculating Noise Doses

When there are multiple noise levels at different periods of time, use a formula similar to the one provided by OSHA (visit regulatory’s website to confirm the accuracy and the most recent version of calculation). Only use periods of time that meet or exceed the threshold of 80dB.

Dose Percentage = (C1/T1 + C2/T2…) x 100 where

Cn = total time of exposure at a specified noise level, and

Tn = exposure duration for which noise at this level becomes hazardous.

The dose can be converted into a 8 hour time weighted average as well using the following formula:

TWA = 10.0 x Log(D/100) + 85

Risk Assessment

NIOSH does not have a single or approved method for conducting noise surveys. However, it states that any method used in risk assessment should follow the guidelines put out by the American National Standard Measurement of Occupational Noise Exposure, ANSI S12.19-1997 .

Hearing Conservation Program

If a noise survey finds that there is an unprotected time weighted average above the recommended exposure time of 85dB, then a hearing conservation program must be put into effect. This program should include annual audits of procedures, assessment of noise exposures, introduction to noise controls, use of hearing protection, monitoring of workers’ hearing, education/training about noise, record keeping and an evaluation of the program’s effectiveness.

Other Federal Agencies with Noise Level Standards

The following noise level standards are examples only. Refer to the respective agency for complete requirements.

US Department of Defense (DoD) Noise Level Standards

The Department of Defense, DoD, has a hearing conservation program in order to prevent hearing loss from operation, including combat, and occupational noise sources in order to facilitate mission readiness,

communication, and safety. According to the DoD, hearing conservation programs should apply to those that meet any of the following criteria:

(1) Continuous and intermittent noise (20 to 16,000 hertz (Hz)) that has an 8-hour time weighted average (TWA) noise level of 85 decibels A-weighted (dBA) or greater.

(2) Impulse noise sound pressure levels (SPLs) of 140 decibels peak (dBP) or greater.

(3) Ultrasonic exposures, which occur under special circumstances that require specific measurement and hazard assessment calculations.

Measurement Standards

The DOD has a number of noise level standards that must be followed for noise measurement and analysis.

Noise should be assessed in all potentially hazardous noise areas and reassessed when operations change that affect noise levels. A risk assessment code will then be assigned to each area. An inventory of each area and its corresponding operation, risk assessment code, noise level, and types of noise control must be logged.

Noise measurements may only be conducted by trained personnel with a sound level meter that possesses an ANSI Type 2 or better microphone. An acoustical calibration that complies with ANSI Standard S1.40 (Reference (j)) must be completed before and after each day’s measurements. An electro-acoustic calibration must have been done to the sound level meter within the last year. When measuring impulse noise, use a sound level meter that meets ANSI Standard S1.4 through S1.4a, has a peak circuit hold, has a rise time not exceeding 35 micro seconds, and is capable of measuring sound pressures over 140dB.

All measurements should be recorded using the A weighting and slow response. When personal dosimeters are used, at minimum, noise levels between 80dB and 130dB should be incorporated into the measurement. Measurements should be conducted for the full length of a shift. Partial shift monitoring should only occur if noise levels are consistent throughout a shift. Compute noise exposure as if no hearing protection is provided. If steady state noise below 130 dB (A Weighted) occurs at the same time as impulse noise above 130dB (c weighted) such as weapons firing, the allowable exposure to steady state noise should not be reduced.

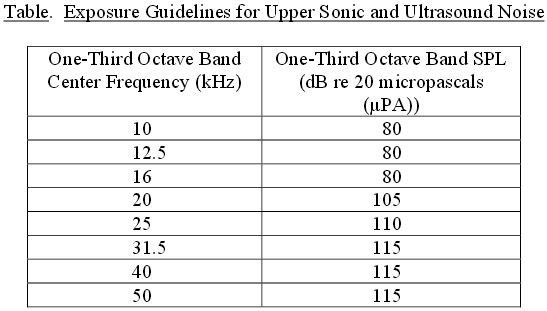

Where upper sonic and ultrasonic noise exposure is prevalent, evaluate the impact of ultrasonic noise and provide hearing protection if limits exceed those in the following table:

Hearing Conservation Program

If a noise survey finds that there is an unprotected time weighted average above the recommended noise level standards of 85dB, impulse noise greater than 140dB, or ultrasonic noise that exceeds allowable limits, then a hearing conservation program must be put into effect. This program includes the marking of hazardous areas, creation of noise controls, incorporation of hearing protection, monitoring of workers’ hearing, education and training about noise, and record keeping.

MSHA Noise Level Standards

The Mine Safety and Health Administration’s goal is to look out for the welfare of those in the mining industry. In keeping with that goal, MSHA has established noise level standards that require a hearing conservation plan to be put into effect when workers are exposed to an action level of eight hour time weighted average of 85dB (A Weighted, slow response) when including all sound levels from 80 to at least 130dB. The Permissible Exposure Level is an eight hour time weighted average of 90dB (A Weighted, slow response) when including all sound levels from 90 to at least 140dB. These two noise level standards are identical to those regulated by OSHA. In addition, if the eight hour time weighted average equals or exceeds 105dB (A Weighted, slow response) when including all sound levels from 90 to at least 140dB then the worker must wear dual hearing protection, ear plugs and muffs. MSHA mandates that no noise shall be more than 115dB at anytime regardless of whether hearing protection is worn or not.

Noise Level Standards Survey

A noise level survey must be conducted to determine if workers meet the action level, permissible exposure level, or dual hearing protection level. All measurements will use the a weighting, slow response, and 5dB exchange rate. Action levels will incorporate all sounds from 80dB to at least 130dB while the other levels will use the 90dB to at least 140dB sound range.

Either sound level meters may be used to find general noise levels in an area or dosimeters can be used to measure representative jobs. In general, dosimeters are more commonly used; however, sound level meters are often used to initially check areas for sources of noise. A preliminary walkaround survey with a diagram of the area will allow the surveyor to learn about the site and plan the best method of survey.

Most dosimeters can be programmed to use different thresholds and calculate daily doses. If a dosimeter cannot be set to record both sound pressure ranges of 80dB to at least 130dB and 90dB to at least 140dB then two dosimeters must be used. Also, dosimeters can keep track of the highest sound level recorded to make sure that no noise exceeds the 115dB maximum. Measurements should be taken within the miner’s hearing zone for the full duration of an eight hour shift. If a sound level meter is used rather than a dosimeter, dose can be calculated using the same formula that OSHA uses. (See example in OSHA section.)

As with any survey, inform the workers of the survey time, date, and its intentions. Let them know that speech will not be recorded and that they should go about their day as normal. Before and after each noise sampling, be certain to calibrate the equipment used. Report results to mining operators/employees as to what levels where found.

When the action level is met, a hearing conservation program must be implemented that includes a system of monitoring, the provision and use of hearing protectors, audiometric testing, training and record keeping.

Coast Guard Noise Level Standards

The Coast Guard has set noise level standards to not only reduce noise induced hearing loss but also to provide a safe working environment that requires intelligent communication and the ability to hear audible alarms and warnings. Because of the unique situation of the maritime industry, the Coast Guard noise level standards are different than those established by other regulatory agencies. The Coast Guard measures the cumulative noise exposure during a complete 24 hour day to consider if the period of time after work time noise provides the necessary quiet time to recoup from the temporary threshold shift. Measurement from a dosimeter over several days is necessary to gain an accurate average.

The 24 hour effective exposure level is expressed as “Leff (24).” The exposure limit enforced by the Coast Guard is 82dB (A Weighted). It is suggested that newly built vessels be designed with a a 77dB noise limit. The exposure limit can be met with engineering noise controls or hearing protection. Engineering controls should always be implemented before hearing protection when economically feasible.

In addition, on vessels larger than 500 gross tons, noise exposure levels should not exceed 75dB in berthing spaces and mess units on existing ships and 70dB on newly built ships. The ship’s fog whistle may not exceed 110dB. Hearing protection devices should be worn in areas at or above 85dB; these area’s should be appropriately marked to avoid accidental exposure. Any exposure over 105dB without hearing protection should be avoided. At no time, should crew be exposed to non-impulse noise of over 115dB or impulse noise of 140dB.

A hearing conservation program should be implemented for anyone that meets the action level of 77dB. Monitoring should occur anytime processes that affect noise change; engineering controls should be implemented when feasible; hearing protection devices should be provided where needed; areas of noise should be marked; education about noise should be provided, and record keeping should be part of this conservation plan.

Federal Motor Carrier Safety Administration Noise Level Standards (DOT)

The Federal Motor Carrier Safety Administration states that the interior sound level at the driver’s seat of a truck, truck-trailer, or bus must not exceed 90dB (A Weighted) when measured as described below.

Park the vehicle at least 50 feet from any surface that will reflect noise such as fences, billboards, buildings, other vehicles, hills, etc. Close all windows, doors and vents; make sure no accessories are running. Place the driver in his seated position. The surveyor can sit in the passenger seat, but all other occupants should leave the vehicle. Use a sound level meter that complies with ANSI 1.4. Orientate the sound level meter 6 inches and on the same plane as the driver’s ear. With the vehicle in neutral, accelerate the engine to its maximum governed engine speed. If there is no governed engine speed, accelerate the engine to its maximum rated horsepower. Stabilize the engine at that speed. If the noise produced has not been compromised by outside noise, record that noise level. Return the engine to idle and then repeat the procedure until two recordings within 2dB are recorded; average these two numbers. This number will be used to determine whether it meets the 90dB limit.

If the vehicle’s engine radiator fan drive is equipped with a device that automatically either reduces the rotational speed of the fan or completely disengages the fan from its power source in response to reduced engine cooling, the vehicle may be parked before testing with its engine running at high idle or any other speed the operator may choose for not more than 10 minutes to in order to allow the radiator fan to disengage.

Federal Railroad Administration (FRA) Noise Level Standards

The Federal Railroad Administration has set noise level standards for locomotive cab noise. These standards state that noise in a locomotive cab should not exceed a 90dB (A Weighted, slow respose) eight hour time weighted average with a 5dB exchange rate. Exposure to continuous noise should not exceed 115dB. Continuous noise is defined as any noise with a rise time of more than 35 milliseconds to peak intensity and a duration of more than 500 milliseconds to the time when the level is 20dB below the peak.

Noise measurements should be made by a sound level meter that meet ANSI 1.4 and Type 2 microphone requirements. All measurements made with A Weighted and slow response settings. Sound level meters or dosimeters used should be positioned on the same axis and within 15 centimeters as a crew member’s ear.

US Environmental Protection Agency (EPA) Noise Product Labeling

The Environmental Protection Agency requires domestic products that make noise or reduce noise to label the noise characteristics of the product. This usually means that manufacturers must affix labels that provide the customer showing the number of decibels that the product emits. Further, the label should provide a noise range in decibels that show the noise range of similar products made by other manufacturers. The lower the decibel on the label, the quieter the product.

In the case of products that reduce noise such as ear plugs or ear muffs, a rating called the “Noise Reduction Rating” will be on the label, which gives a measurement of the product’s effectiveness in reducing noise. Likewise, this rating will be accompanied by a range noise reduction ratings for competing products. The higher the rating, the more effective the product should be.

In general, the EPA puts an emphasis on requiring labels on products used in and around the home such as tools, household appliances, and lawn and garden equipment. The EPA expects manufacturers to be responsible for conducting their own noise tests and affixing the proper labels. However, the EPA can monitor manufacturer’s tests, facilities, records, and labeled products. Orders such as retesting, re-labeling, and even product recall can be made for manufacturers that mislabel their products.

The Environmental Protection Agency specifies that products that produce or reduce noise must include labeling that meets the following criteria:

(a) The term “Noise Rating” if the product produces noise or the term “Noise Reduction Rating” if the product reduces noise.

(b) The acoustic rating descriptor.

(c) Comparative acoustic rating information.

(d) A product manufacturer identification consisting of: (1) The Company name, and (2) The City and State of the principal office.

(e) A product model number or type identification.

(f) The phrase “Federal law prohibits removal of this label prior to purchase.”

(g) The U.S. Environmental Protection Agency logo.

(h) The phrase “Label Required by U.S. EPA regulation 40 CFR part 211, subpart ___.